A New Boiler

Although a new boiler generally requires using a registered design there is provision to use a “grandfathered” design. That is making an exact replica of an existing boiler predating the introduction of registered designs. Provided we replicated the existing boiler we are able to rebuild without having to submit the design for engineering certification or to follow present day design restrictions. This means it must be a fully riveted boiler.

First off was to get the tube plates made. It was a struggle to find somewhere to flange the tube plates in boiler plate with the required radius and depth. One manufacturer suggested just pressing the curve and welding a skirt on but the boiler inspector was not happy with this especially as the rivets would be on the weld seam. Eventually we found someone who could do the job. He hot flanged them at 950C. It was quite spectacular to watch. We had to have a former machined to the right dimensions. This took a large lump of steel so to reduce costs we had the outer tube plate pressed then the former machined down for the firebox tube plate.

The manufacturer made two pressings for each plate just in case. This was done in March 2020 at the start of the pandemic.

See it on youtube

https://www.youtube.com/watch?v=Fgb_zoORRus

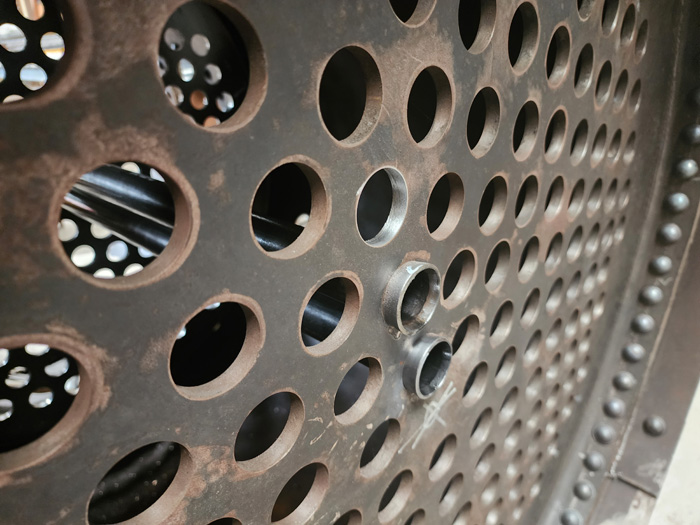

A series of lockdowns stalled progress. Next came getting the tube holes drilled. The 170 tube holes are not in a completely regular pattern allowing gaps for various fittings. To ensure that the hole pattern matched top to bottom tube plates we used computer software to generate a drawing to have them cut on a CNC mill.

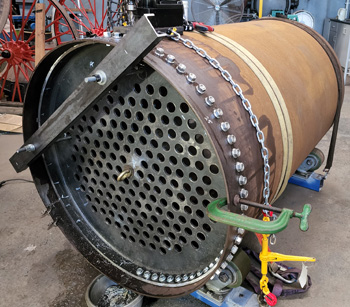

With the shells rolled the next step was to put it together. We have only limited experience of riveting and decided to look for someone to take over the construction. We found that commercial outfits prepared to make a fully riveted boiler were thin on the ground. Those who could had long waiting lists or were unable to commit to a price or timeframe. Initially we settled on Ainsworth Engineering, a Goulburn firm who we were confident could handle the job. We took it up in February 2021 but a few weeks later they were experiencing a financial crisis and had called Toll to come and collect the boiler and ship it back to us to ensure it did not get caught up in a possible receivership. Although the crisis passed,the firm had lost their experienced boiler maker and decided to concentrate on other aspects of their business. Ken Ainsworth was willing to give any advice needed so lacking other options Ross took up the task and cracked on at drilling and bolting up ready for riveting. Ross set the shell up on rollers to keep it steady and allow him to rotate it and align the magnetic drill to drill the rivet holes. He drilled and bolted the shell and tube plates for both the outer shell and the firebox.

We next looked for someone to rivet it for us. Although we had done a little riveting in the past we felt this was too much for us. Also we were keen to use a rivet squeezer as recommended in the code. An MSTEC member put us on to Huntington Engineering at Mt Compass in South Australia where Simon Huntington had a suitable squeezer. Initially we had the outer shell and firebox riveted.

Back home Ross drilled and bolted the shells into the foundation ring and we returned to SA to have them riveted.

While we were over there and once the firebox was in place Ross and Jo drilled the holes for the stays, Simon machined up the stays and we returned to Melbourne with the boiler ready for putting in the tubes and drilling penetrations for the various fittings.