Buffalo Pitts portable

This engine comes out at rally times to run a stone crusher. The photo of it as aquired shows our then 3 year old proudly on top. The engine has a lot of interesting features that are typical of American manufactured engines but not common on British engines. The big steam dome is never seen on British engines and the relatively small flywheel likewise. The mounting of the cylinder on the side of the boiler is unusual, too, but makes it more accessible. The engine exhaust passes through a feed water heater, A less desirable feature of the boiler is the "wet" firebox. Where as British boilers were open under the firebars, in this boiler the water space wraps right around the firebox enclosing the area under the firebars. This means that you cannot knock out the firebars and get at the firebox from under the engine. The only access is through the firebox door. It also means that when housekeeping practises were not good the fireboxes soon rusted through on the bottom. This engine had some very "agricultural" repairs to the boiler in this area. The seat at the front of the boiler puts the machine into historical perspective. It is clearly from pre tractor days. This is the drivers seat from where he controlled the horses towing the engine. A foot assisted handbrake helped keep the engine from over running the horses coming down the hills.

This engine comes out at rally times to run a stone crusher. The photo of it as aquired shows our then 3 year old proudly on top. The engine has a lot of interesting features that are typical of American manufactured engines but not common on British engines. The big steam dome is never seen on British engines and the relatively small flywheel likewise. The mounting of the cylinder on the side of the boiler is unusual, too, but makes it more accessible. The engine exhaust passes through a feed water heater, A less desirable feature of the boiler is the "wet" firebox. Where as British boilers were open under the firebars, in this boiler the water space wraps right around the firebox enclosing the area under the firebars. This means that you cannot knock out the firebars and get at the firebox from under the engine. The only access is through the firebox door. It also means that when housekeeping practises were not good the fireboxes soon rusted through on the bottom. This engine had some very "agricultural" repairs to the boiler in this area. The seat at the front of the boiler puts the machine into historical perspective. It is clearly from pre tractor days. This is the drivers seat from where he controlled the horses towing the engine. A foot assisted handbrake helped keep the engine from over running the horses coming down the hills.

The boiler was in good condition apart from the ashpan area and thinning around where the fusible plug had leaked. View of the under neath of the ashpan showing how the farmer had "repaired" the boiler by putting a patch with a gasket on the fireside of the ashpan and bolting it right through the water space.

The entire area was removed on both the inner and outer firebox wrapper and a patch welded on by a coded welder. Jo and Ross then riveted it before the outer firebox patch was welded on.

Space is tight in the firebox

After putting the project aside for some years we got a nudge from our son and decided to get on and finish it.

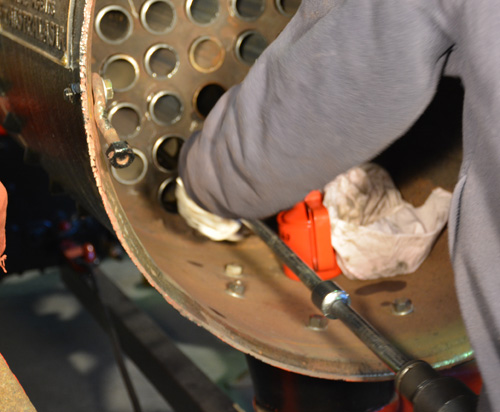

Next job was the tubes.

Our boiler inspector wanted a couple of patch welds done and recommended a coded welder who was looking for a few hours weekend work. The welder was also happy to give Ross a hand putting in the tubes. He came with a handy pneumatic drive with torque control and between them they got all the tubes in in just a couple of hours

It was finally finished and out driving a stone crusher for MSTEC 2016 steamfest. Young son was now in his mid 30's.